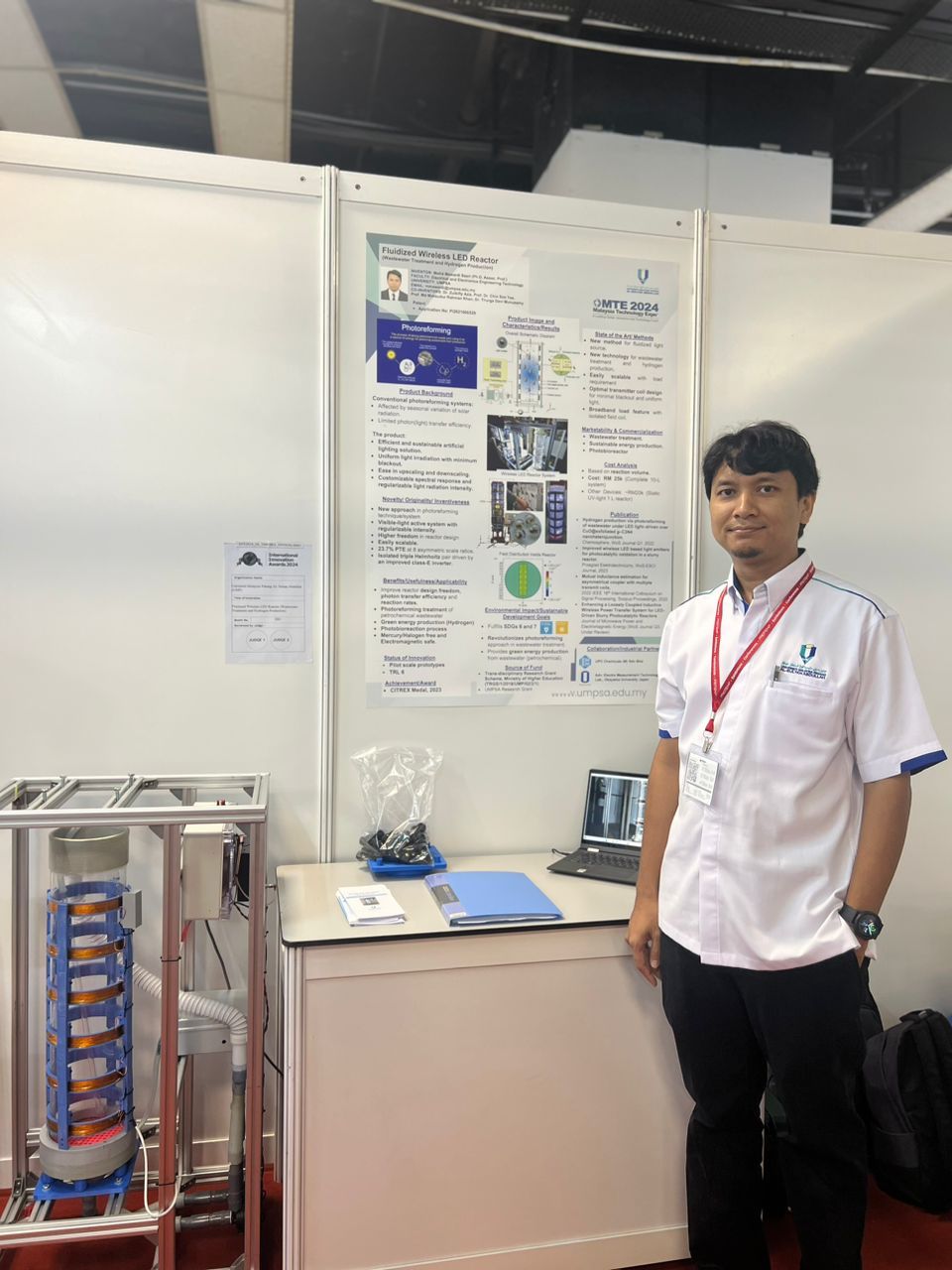

Associate Professor Dr. Mohd Mawardi uses LEDs to develop photocatalytic reactor as source of white light (photon)

PEKAN, 25 June 2024 – Researcher and lecturer of the Faculty of Electrical and Electronic Engineering Technology (FTKEE), Universiti Malaysia Pahang Al-Sultan Abdullah (UMPSA), Associate Professor Dr. Mohd Mawardi Saari, 37 designed a photocatalytic reactor using LEDs as a source of white light (photons).

According to this Kelantan-born lad, the LEDs are powered by a wireless power transfer system and move freely within the reactor area to activate the photoreforming process by the photocatalyst.

“Through my research titled Fluidized Wireless LED Reactor (Wastewater Treatment and Hydrogen Production), this product works by converting DC electrical energy to AC at high frequencies using an inverter developed specifically for this project.

“This AC electrical energy is then transmitted to the transmitter coil on the outside of the reactor to uniformly convert electrical energy into magnetic energy within the reactor area.

“Then, through the concept of induction, this magnetic energy is received by the receiving coil and converted and returned to electrical energy to turn on the LEDs,” he said, who has a Doctorate (Engineering) from Okayama University, Japan.

Associate Professor Dr. Mohd Mawardi said these LEDs will then convert electrical energy into light (photons) to activate the photocatalyst for the photoreforming process.

“The five-year research, which began in 2018, was a spark of original ideas from a group of researchers led by the lecturer of the Faculty of Chemical and Process Engineering Technology (FTKKP), Professor Ir. Dr. Chin Sim Yee aimed to overcome problems in conventional photoreactors.

“Among the problems are the inconsistent dependence of the sunlight source and the weak penetration of light into the reactor when the light source is placed outside the reactor.

“These problems sparked the idea to use a light source inside the reactor and move freely to achieve a more even photoreforming process.

“Our group progressed from that point and was given the responsibility to produce a photoreactor based on these characteristics,” he said.

The research was conducted under a subproject of the 2018 TRGS Grant in collaboration with Professor Ir. Dr. Chin Sim Yee (FTKKP) and two PhD students, namely Zulkifly Aziz (FTKEE) and Thurga Devi Munusamy (FTKKP).

He further explained that the end goal of this product is to be one of the technologies that can be used for the water treatment process by petrochemical plants using photoreforming methods.

“At the same time, it helps the production of hydrogen.

“This is in line with the Sustainable Development Goals (SDG) 6 and 7 for water treatment innovation and producing clean energy.

“In fact, we will promote and open for any discussions and collaborations related to this product technology to the industry and research institutions,” he said, who specialises in the field of magnetic sensor instrumentation.

This research also involves collaboration between industries, namely UPC Chemicals (M) Sdn. Bhd., and technically on the instrument side, the collaboration is carried out with Adv. Electro Measurement Technology Laboratory, Okayama University in Japan.

“The estimated cost is around RM25,000.00 for 10 litres of reactor volume.

“In the future, we plan to expand the use of the concept of wireless energy transfer technology and hope that the products developed can be applied in industry and research institutions.

“Our research group at FTKEE also has expertise in the study and production of probes for nondestructive testing of iron components.

“In addition, our group has expertise in producing prototypes based on magnetic sensors and sensing instruments,” he said.

For the record, this research won a silver medal at the 2023 Creation, Innovation, Technology & Research Exposition (CITREX), a gold medal and also a Special Award from the Union of Arab Academia at the 2024 Malaysia Technology Expo (MTE).

By: Safriza Baharuddin, Centre for Corporate Communications

Translation by: Dr. Rozaimi Abu Samah, Faculty of Chemical and Process Engineering Technology

- 78 views

Reports by:

Reports by: