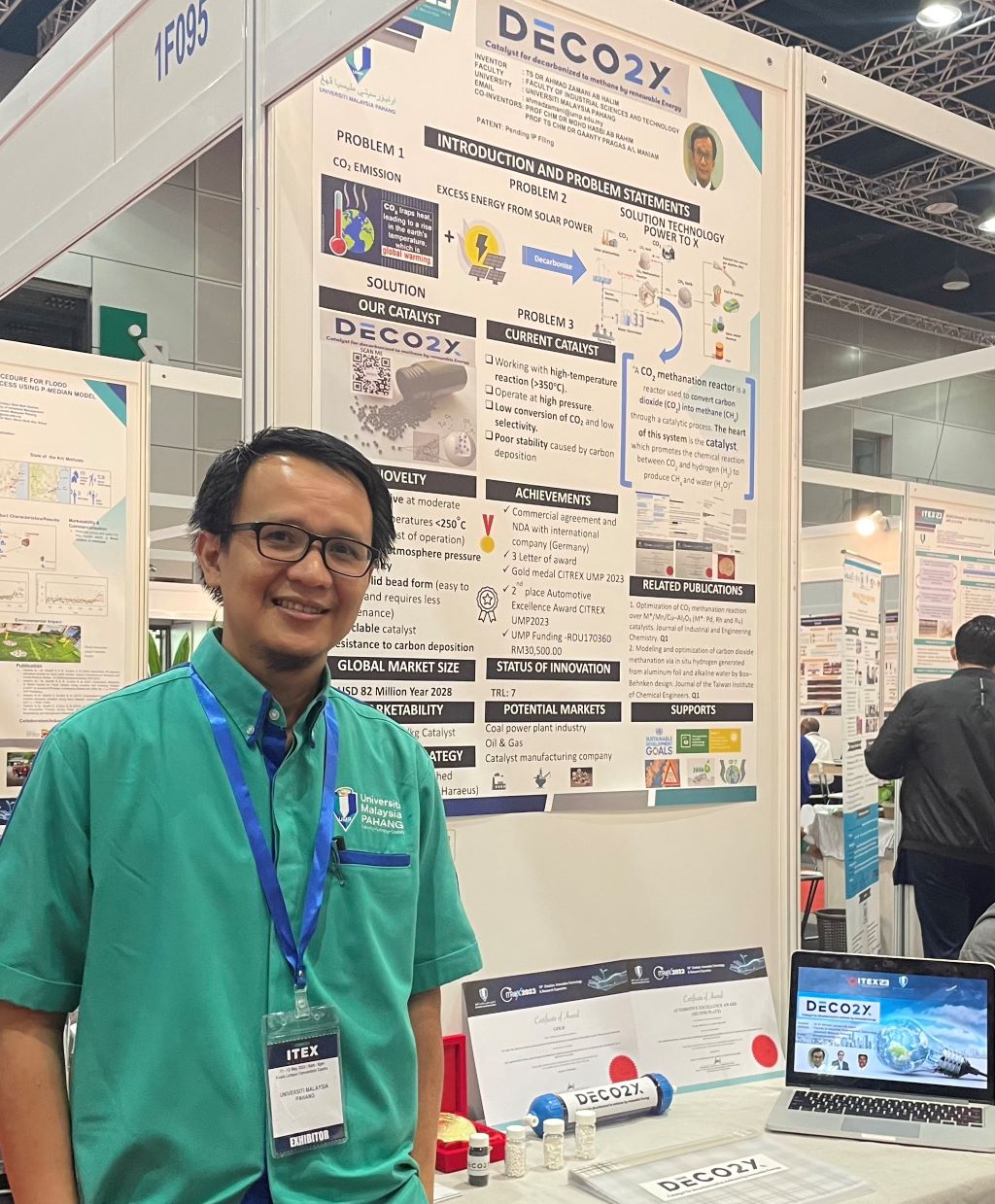

Ts. ChM Dr. Ahmad Zamani invents DECO2X, a catalyst to convert carbon dioxide into methane

GAMBANG, 19 December 2023 - Energy-to-product technology (Power to X) is the best technology that uses renewable energy sources such as solar or wind energy to convert carbon dioxide combined with hydrogen into other products such as methane, methanol and others.

This technology can solve the problem of carbon dioxide emission into the environment in line with the net zero carbon policy by 2050.

According to the Faculty of Industrial Science and Technology (FSTI) researcher and lecturer, Universiti Malaysia Pahang Al-Sultan Abdullah (UMPSA), Ts. ChM Dr. Ahmad Zamani Ab Halim, converting carbon dioxide to methane usually requires a catalyst and operates at high temperatures (>350 °C) as well as high pressures, causing it to be cost inefficient for use in industry.

“In addition, carbon is deposited on the catalyst surface, blocking its active area.

This reduces its catalytic and effective activities.

“DECO2X catalyst material is formulated to solve the problems faced by the industry in finding effective catalyst materials that operate at low temperatures as well as to address greenhouse effect problems.

"DECO2X is produced by combining several metal oxides that have active areas that can convert carbon dioxide into methane,” said this Terengganu-born.

This research was conducted from 2018 to 2022.

According to Dr. Ahmad Zamani, the idea to conduct this research started from the increase of carbon dioxide emission into the environment that causes greenhouse effects such as global warming and unpredictable weather.

“Furthermore, petroleum fuels are decreasing and new fuels from renewable energy sources are very much in need.

“Thus, the active ingredient of DECO2X catalyst is formulated with a combination of metal oxides, which can operate at low temperatures.

“The methane gas produced can be distributed to natural gas grid pipes to increase the methane gas composition so that we don’t solely depend on methane gas from petroleum sources,” he said.

He said that this methane gas can also be used as a vehicle fuel, cooking fuel, and also as a combustion material for steam turbine generators to produce electricity.

“I conducted this research together with Professor Dr. Mohd Hasbi Ab Rahim and Professor Ts. Dr. Gaanty Pragas s/o Maniam from FSTI.

“Simply put, DECO2X is a catalyst material that has been formulated with several metal oxides.

“This catalyst has an active ingredient that can convert carbon dioxide mixed with hydrogen into methane at a low temperature of less than 250 °C (usually 350 °C) and can convert between 85% and 90% of carbon dioxide to methane,” he said.

Furthermore, the catalyst is stable and has no carbon precipitation problem on its surface.

“Apart from the low operating temperature, it operates at a normal pressure of 1 bar.

“This study aims to enable the catalyst application in all industries that emit carbon dioxide with the hope of achieving zero carbon dioxide emission in line with the net zero carbon policy by 2050.

“We aim to work with industries that emit a lot of carbon dioxide such as the power plant industry, oil and gas to use these catalysts,” he said.

The application of DECO2X catalysts in the energy-to-product technology benefits the industry in reducing carbon emissions.

In addition, the industry benefits from the government’s initiative that introduced carbon tax.

For those interested in DECO2X, he currently sets a price of RM2,000/kg.

He has also previously produced other products such as a new natural gas upgrading system (biogas) from food waste, catalysts for dry reforming methane gas to syngas, and graphene production from palm oil solid waste sources.

For the record, this product won a gold medal in the 2022 Creation, Innovation, Technology and Research Exposition (CITREX) Competition and a silver medal in the 2023 International Invention, Innovation and Technology Exhibition (ITEX).

By: Safriza Baharuddin And Nur Hartini Mohd Hatta, Centre for Corporate Communications

Translation by: Dr. Rozaimi Abu Samah, Faculty of Chemical and Process Engineering Technology

- 184 views