Dr. Amiril Sahab produces 5 products from Tamanu tree seeds

PEKAN, 19 October 2022 - Tamanu tree (Bintangor Laut) is a common plant on the east coast as it grows abundantly along the east coast of Peninsular Malaysia.

This project is easily implemented at Universiti Malaysia Pahang (UMP) because the readily available resource of Tamanu fruit trees around UMP can be harvested throughout the year.

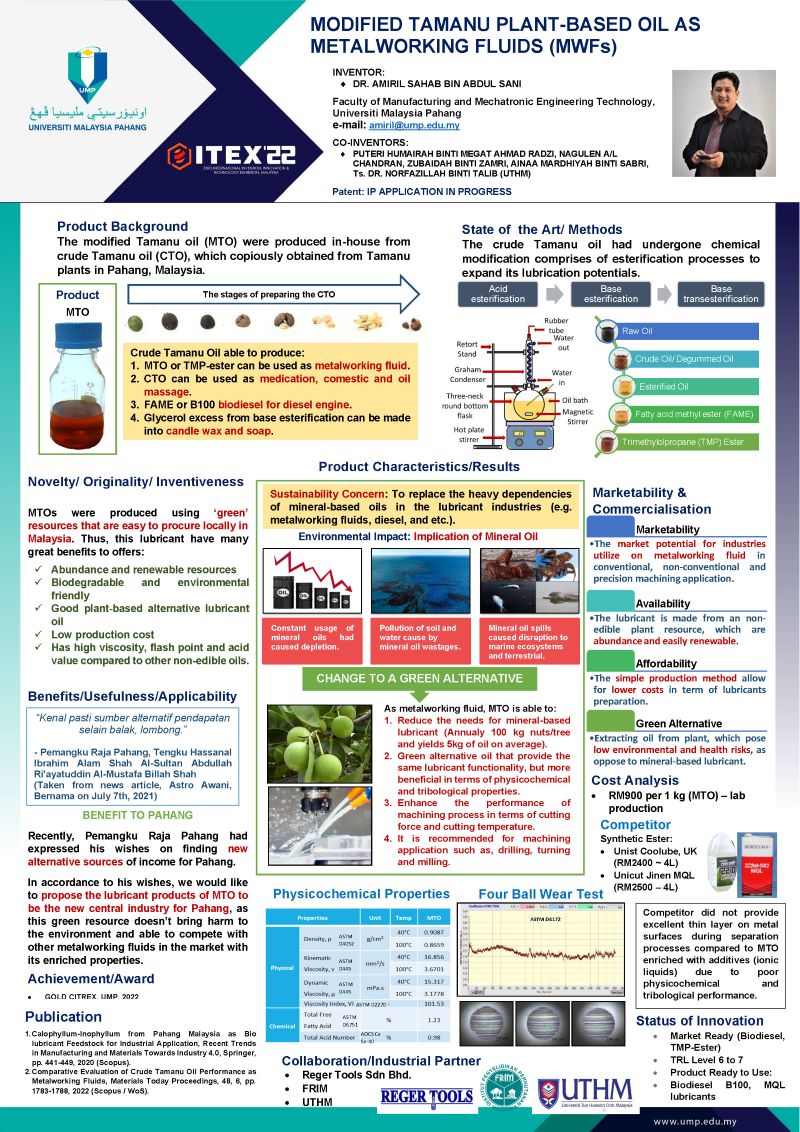

Starting from this finding, the lecturer of the Faculty of Manufacturing and Mechatronic Engineering Technology (FTKPM), Dr. Amiril Sahab Abdul Sani, 38, has produced five products for different uses that include commercial and industrial uses resulting from the extract of Tamanu tree oil.

The five products are virgin oil (lamp oil, traditional massage oil), natural rubber-free oil (lamp oil, pharmaceuticals), low-acid oil (pharmaceuticals), Tamanu biodiesel (B100), and synthetic ester oil (manufacturing industry lubricant).

This research also received the collaboration of lecturers and vocational training officers of FTKPM, UMP, University Tun Hussein Onn Malaysia (UTHM) lecurer, Ts. Dr. Norfazillah Talib, and UMP students under his supervision.

According to Dr. Amiril, this research is closely related to the sustainability of processes and materials in the manufacturing industry and the main goal of this research is related to the use of easily biodegradable and renewable green materials.

“The use of petroleum-based raw materials and mineral oils in the processing and production of lubricating oils for industrial use in manufacturing has a negative impact on the sustainability of the manufacturing industry ecosystem (increasing crude oil prices, high potential for getting skin cancer, bronchitis) and the survival of marine life due to disasters on the open seas (pollution from oil spills).

“Vegetable-based oils are the choice of researchers as an alternative source to the use of finite resources (petroleum).

“Inedible vegetable oils are the main ingredient compared to edible oils such as palm oil, corn and others.

“This project started in early December 2018, two weeks after I started my career as a lecturer at UMP,” he said.

Initially, he along with Dr. Ahmad Shahir Jamaludin and Dr. Ahmad Najmuddin Ibrahim formulated the idea almost a year before applying for the FRGS grant in 2019, which was approved in September of the same year and continues to be developed until now.

“Starting with the manual production process, this project has evolved and various machines have been successfully developed at FTKPM, UMP by students and produced more than ten undergraduate, master’s and doctoral theses as a result of a joint venture with research partners at UTHM.

“The oil project is expected to be fully completed by the end of 2022.

“My first visit as a UMP lecturer to the Forest Research Institute Malaysia (FRIM) in early 2019 was the starting point for this research,” he said.

He further added that this research is seen to provide its own benefits to the society, individuals and industries.

“The advice and guidance from FRIM were a tremendous help in further expanding the project.

“This year, a collaboration with the industry side, Reger Tools Sdn. Bhd. was initiated regarding the use of the oil to study the oil validity during the iron-cutting process,” he said.

Dr. Amiril explained the first, second and third products from Tamanu tree oil are natural oils from Tamanu seed extract and can be used traditionally and in the pharmaceutical field.

“The fourth product is Tamanu biodiesel (B100) from Tamanu oil extract with B100 biodiesel properties that meet international standards, namely ASTM D6751.

“The last product which is synthetic ester oil (manufacturing industry lubricant) from Tamanu oil extract is a vegetable-based synthetic ester that has been formulated to help smoothen the surface of iron when cut (metal separating process).

“Tamanu ester oil is sprayed using an aerosol spray machine called the minimum lubrication spray technique or minimum quantity lubrication (MQL) technique,” he said.

He added that the machines involved in the semi-automatic production of this oil are the heat-drying machine (drying the fruits and seeds), the machine for separating seeds from fruit (breaking the fruits and isolating the seeds) and the oil press machine.

“Tamanu fruit oil extract can be utilised by the local community when the fourth (biodiesel) and fifth (Tamanu-based synthetic esters) products are successfully commercialised.

“This commercialisation not only helps the economy of the community, but also promotes community involvement in producing world-class local products.

“The manufacturing of automatic machines can also be utilised by the community with involvement in developing more established products,” he said.

“In addition, natural Tamanu oil can be utilised for traditional uses and in the pharmaceutical field.

“I am certain that the results of research on new sources of renewable energy from Tamanu trees can still be further developed because there are several other functions that can be utilised from Tamanu fruits and leaves such as the production of compressed charcoal, activated carbon-based additives and others.

“The sales cost for each product is RM350/kg for virgin oil (lamp oil), RM450/kg for rubber-free natural oil (lamp oil, pharmaceuticals), RM500/kg for low-acid oil (pharmaceuticals), RM750/kg for Tamanu biodiesel (B100) and RM900/kg for synthetic ester oil (manufacturing industry lubricant),” he said.

According to him, industrial collaboration and UMP would enable the commercialisation of the products and machines developed in this project.

“The local community can be equally involved in economy generation with the production of Tamanu fruit and tree crops which are synonymous with the coastal environment of Pekan, Pahang,” he said.

This research won a gold medal in the Creation, Innovation, Technology and Research Exposition (CITREx) 2021.

The research also won a gold medal at the International Invention, Innovation and Technology Exhibition (ITEX) 2022 which took place at the Kuala Lumpur Convention Centre (KLCC) on 26 and 27 May 2022.

By: Nur Hartini Mohd Hatta, Corporate Communications Division, Chancellery Department

Translation by: Dr. Rozaimi Abu Samah, Engineering College/Faculty of Chemical and Process Engineering Technology

- 311 views