UMPSA researchers discover synthetic graphite from palm biomass, new opportunity for high-growth high-value (HGHV) sector

PEKAN, 1 December 2025 – Researchers from Universiti Malaysia Pahang Al-Sultan Abdullah (UMPSA) have successfully developed a method to produce synthetic graphite using oil palm fronds (OPF) and palm kernel shells (PKS), focusing on the conversion of biomass waste at lower temperatures without the use of hazardous chemicals.

This first-of-its-kind discovery in Malaysia is expected to boost the growth of the high-growth high-value (HGHV) industry and other high-impact strategic sectors.

Global demand for natural graphite continues to increase due to the rising production of energy storage devices such as lithium-ion batteries, which are widely used in smartphones as well as electric vehicles (EVs) that are now rapidly increasing in the country.

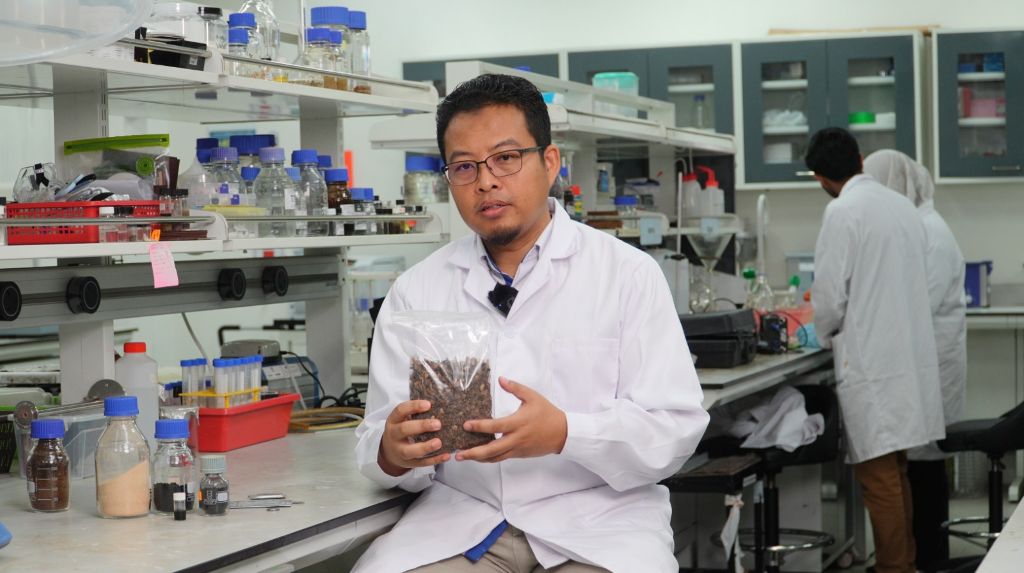

This project is led by Professor Dr Jose Rajan, Principal Research Fellow of the Centre for Advanced Intelligent Materials (CAIM) and professor at the Faculty of Industrial Science and Technology (FSTI), who has expertise in renewable energy devices, sustainable materials, circular economy, data science, and artificial intelligence.

This study also received support from other researchers, including ChM. Dr Izan Izwan Misnon, who is the Director of CAIM, and postgraduate students comprising Dawn Sivan, Gayathry Ganesh, Saima Zafar, Cherraka Ashwati, and Mohammad Ullah.

According to Professor Dr Jose Rajan, in the manufacture of lithium-ion batteries, approximately 28 per cent of their composition consists of graphite, which functions as the anode or negative terminal.

To address the shortage of natural resources, the production of synthetic graphite from biomass waste has now emerged as an alternative with great potential.

He said that Malaysia has a competitive advantage in this field as the country produces approximately 127 million tonnes of palm biomass annually.

According to him, the research team has optimised synthesis protocols to produce substitute materials for natural graphite for use in energy storage electrodes.

“Typically, carbon graphitisation processes require temperatures exceeding 2500 °C.

“However, in this study, palm biomass was treated at temperatures below 1100 °C to enable the formation of graphitic structures.

“This opens opportunities for the production of more sustainable synthetic graphite with lower production costs compared to natural sources,” he said.

He added that other industries, such as steel, lubricants, pigments, and electronics, also have high demand for graphite.

“The development of graphitic carbon from biomass also supports the concept of a circular economy, where agricultural waste can be converted into value-added products,” he said.

This effort is also aligned with the Sustainable Development Goals (SDGs), particularly Affordable and Clean Energy (SDG7), as well as the national electrification agenda.

Meanwhile, the UMPSA research team has also successfully demonstrated the application of this synthetic graphite in supercapacitors.

The developed device demonstrated strong performance with an energy density of 36 Wh/kg, a power density of 2,400 W/kg, and high stability after 10,000 cycles.

They are now focusing on the development of lithium-ion and sodium-ion batteries to optimise the material properties produced from this palm biomass.

This innovation also received financial support from the university through the UMPSA First in the World Flagship programme to further strengthen the university’s position as a leader in advanced technology in Malaysia.

The results of this research have been published and referenced internationally in high-impact journals, including Journal of Energy Storage, ACS Sustainable Resource Management, and Journal of Electroanalytical Chemistry.

The related technology for material synthesis and its application in energy storage has also been patented recently.

UMPSA continues to focus on strengthening research and development to maximise positive impact in line with the university’s slogan, ‘Technology for Community’.

This discovery not only strengthens Malaysia’s potential in the high-growth high-value (HGHV) sector but also proves that the country’s palm waste can become a strategic resource for future energy technologies.

By: Mimi Rabita Abd Wahit, Centre for Corporate Communications

Translation by: Ts. Dr Rozaimi Abu Samah, UMPSA Press

- 44 views

Reports by:

Reports by: