Campus Info UMP contributes 10 thousand pieces of medical gloves to a hospital at Hebei University, China

By: FATIN ZAHIRAH MANSUR, ACADEMIC AND INTERNATIONAL AFFAIRS DEPARTMENT Universiti Malaysia Pahang (UMP) contributed 10 thousand pieces of medical gloves to a hospital at Hebei University, China, due to the outbreak of coronavirus or also known as Covid-19. The UMP Vice-Chancellor, Professor Ir. Dr. Wan Azhar Wan Yusoff handed over the medical gloves to Professor Dr. Guo Fuliang, the Director of China Confucius Institute (CI) UMP, who is also a Professor from Hebei University. The handover ceremony was held at Confucius Institute UMP Pekan campus on 11 March 2020. Hebei University is the strategic partner of UMP to collaborate with the Confucius Institute in UMP. Malaysia is the world’s largest manufacturer of medical gloves. UMP took the initiative to donate medical gloves to a hospital at Hebei University as China is currently facing a shortage of medical supplies. UMP hoped to assist China in combatting Covid-19. “We wish Covid-19 will be under control in China, and all other countries will be free from the virus,” he said. Academic and International Using technology and e-Learning maximise learning experience impact

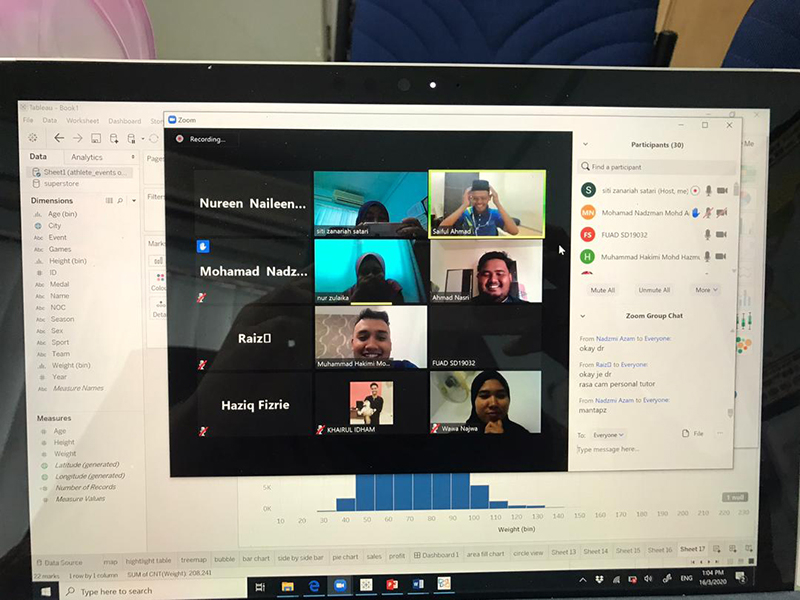

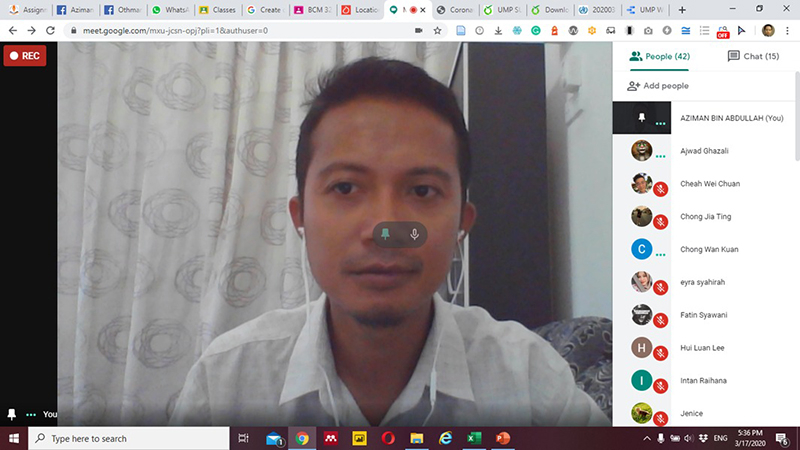

Translation by: DR. ROZAIMI ABU SAMAH, FACULTY OF CHEMICAL AND PROCESS ENGINEERING TECHNOLOGY Lecturers of Universiti Malaysia Pahang (UMP) activated virtual classroom (e-Learning) for all teaching and learning activities on 17 March 2020. The switch was due to the announcement through the Administrative Circular No. 3/2020 issued by the university to tackle the spread of Covid-19.

A lecturer from the Faculty of Computing, Ts. Aziman Abdullah, uses online e-Learning mode via UMP Knowledge and Learning Management System (KALAM) and Google Classroom. “Google Classroom is more convenient for notifying, giving feedback, and assessing students’ work. Meanwhile, KALAM is used for the purpose of accreditation or official university matters,” he said. For instance, he designed the learning activities in the form of preparing proposals. “Students need to do their work during the session scheduled to complete within the stipulated time without having to go to the classroom. “Lecturers should use e-Learning technology to maximise the impact of meaningful learning experience among students. “Besides, this approach is practical not only during this restricted time such as the threat of an outbreak but also convenient during regular lecture sessions,” he said. He added that the biggest challenge in e-Learning is the attitude and mentality of educators who resist changes and stay in their comfort zone of using the existing methods.

Meanwhile, the Deputy Director of the Centre of Instructional Resources and e-Learning (CIReL), who is also a lecturer from the Faculty of Computing, Ts. Dr. Awanis Romli opted for Google Meet for her online class with her students recently. She was overwhelmed with the encouraging students’ feedback that they were happy with the approach of online learning because they can learn anywhere. “Furthermore, UMP subscribes G Suites for Education that allows lecturers and students to use all the applications for free,” she said. Similarly, a lecturer from the Faculty of Industrial Management (FIM), Dr. Suhaidah Hussain, said that the learning session was executed smoothly. “This approach helps lecturers and students to continue to learn virtually without interrupting the class schedule. “In addition, tutorials and forums can be carried out using KALAM. “The main challenge was the limited internet coverage in certain areas. However, it is not an obstacle for lecturers and students to continue learning by utilising the current technology,” she said. In accordance with the announcement made by the Prime Minister on 25 March 2020 on the extension of the enforcement of the National Movement Control Order and the temporary closure of all Public Higher Education Institutions in Malaysia, Universiti Malaysia Pahang (UMP) is suspending all of its service operations from 18 March to 14 April 2020. Accordingly, all teaching and learning sessions including online learning, in UMP are suspended during the National Movement Control Order period. UMP will also make amendments to the academic calendar for Semester II, Session 2019/2020 and the details will be notified later. Students Activities UMP volunteers handle Campus Pantry for students benefit

Edited by: DR. ROZAIMI ABU SAMAH, FACULTY OF CHEMICAL AND PROCESS ENGINEERING TECHNOLOGY A total of 200 volunteers consisting of 110 volunteers from UMP Gambang Campus and 90 from UMP Pekan involved in the establishing UMP Campus Pantry at both campuses on 13 March 2020. They were divided into two groups that managed dry foods and daily necessities such as detergent, toothbrushes and soaps, and the other group managed wet foods such as vegetables, fruits and fish. According to the Head of Volunteers, Ikmal Shauqi Burhan, 20, the volunteers were brought to Pasar Besar Kuantan as early as 7.30 am to get the leftover vegetables from the grocers or donors. “The food supplies will be taken to UMP Mosque for preprocessing before being distributed to the UMP students who live off campus. The distribution is done at around 4.00 pm because this the usual time that a few students return from lectures,” he said. The volunteers on duty will ensure food such as bread, biscuits and essential items are in good condition and arranged in the space provided.

He and his team thanked UMP for the care and concern for the welfare of students at the university. Meanwhile, the Deputy Vice-Chancellor (Student Affairs and Alumni), Professor Dato’ Dr. Yusserie Zainuddin said that UMP has started this Campus Pantry before the Ministry of Domestic Trade and Consumer Affairs launched Food Bank in UMP. “UMP Campus Pantry provides wet and dry foods contributed by various agencies, UMP associates, individuals and supermarkets. “At the same time, we also receive donations from UMP Foundation that helps UMP Campus Pantry a lot. “Until now, a total or 1,500 students have benefited from UMP Campus Pantry, and the number is growing day by day. As we have 60 percent students from the B40 class with less than RM3,000 monthly earning,” he said. He also emphasised that 28 percent of the students come from the families with less than RM1,000 monthly earning. “So, it really helps ease their burden.

“UMP Campus Pantry is now open in the morning session as well and all the items are all taken by students. “Students who have financial problems and wanted to get food supplies just need to come here and take it by simply registrering in the system provided,” he said. For one of the contributors, Tan Kwai Loon, who is also an alumnus of UMP, every week he contributes almost 300 kg of vegetables such as cucumbers, green mustards, water spinach, bitter gourd, chillies and many more. “The vegetables are the leftover that can still be used and they are local produce at individual farm,” he said. The Student Affairs and Alumni Department (JHEPA) will always ensure an adequate supply especially towards the end of the semester, when most students in greater need of food and money during this time. Around Campus Info UMP targets 4 strategic objectives towards the best technological university by 2050

Edited by: DR. ROZAIMI ABU SAMAH, FACULTY OF CHEMICAL AND PROCESS ENGINEERING TECHNOLOGY Universiti Malaysia Pahang (UMP) has laid the foundation in achieving excellence for UMP Strategic Plan 2021–2025 by targetting four main objectives, which are (1) producing holistic community-driven graduates through high-level Technical and Vocational Education and Training (TVET), (2) communitising technology, (3) generating new advanced technologies via research initiatives, and (4) achieving financial and best practices sustainability. In line with the UMP vision of becoming the best technological university by 2050, the UMP Vice-Chancellor, Professor Ir. Dr. Wan Azhar Wan Yusoff emphasised that the university must have the world-class characteristics and most importantly is to have sustainable financial resources as well as autonomous status. “With that, we can gather not only students but also lecturers as the world’s first technology specialists. “It makes UMP well known, and Pekan will be famous someday. “At that time, UMP is capable of producing highly reputable graduates who are pioneers and sources of reference for global technology and problem solving, and this is the epitome of a university,” he said while implying the future of a university. He added, “The university management system is also respected, efficient and effective, as well as enhances the dignity of a leading university. “Therefore, we have to be smart in finding ways to freely strengthen the financial sustainability of RM5 billion target to move independently. “UMP has a vision of being the best technological university by 2025 with a target of 90 percent of its lecturers with a doctorate (PhD) degree. “It can be reflected through reputable and relevant graduates and the service to the global community.” He also said that UMP currently has over 86 percent of lecturers with PhD and in realising the target by 2050, the university must develop talent as field specialists in inventing new technologies and developing an efficient, effective and respected management system that optimises talents to uplift the university. “This expertise will be referred, and programmes to develop the experts will be built,” he said. Delivering Amanat Tahunan Naib Canselor 2020 on 15 February 2020, Professor Ir. Dr. Wan Azhar said that based on records of the Ministry of Education Malaysia (MOE), UMP achieved the highest graduate employability status, where 96 percent of the graduates are employed within 6 months after graduation. “This target should be maintained in 2025 at a minimum of 90 percent, but the university must scrutinize those who receive a job offer before graduation. “The students are not only evaluated academically but also targeted to achieve 80 percent i-CGPA to possess comprehensive abilities that are built from other skills, which include soft skills such as communication and bilingual, as well as a third language. “In addition, the university aims to focus on volunteerism, sustainability and environmental care, and other criteria set in X-CGPA,” he said. He added, “We will also measure the student’s ability through the concept of major–minor. “These minor programmes allow technical students to talk about the economy, finance, and those that complement their current courses, by utilising the expertise of UMP lecturers to develop talents and produce holistic and global students. “In the meantime, UMP will provide an opportunity for the public to join programmes involving industry and academic.” In increasing the number of collaborations with international universities especially in Germany and China via Dual Degree Award in each faculty, in addition to the partnership with the Karlsruhe University of Applied Science (HsKA) Germany, the collaboration with SIASUN Robot & Automation Co. Ltd. in Shenyang, China, as well as educational institutions in China allows students to complete two years of study in UMP, one year in China and another year for industrial training in SIASUN. According to Professor Ir. Dr. Wan Azhar, UMP is clustered under the Malaysian Technological University Network (MTUN) to enable the technical capabilities of the country through high-level TVET programmes. “To enable the capability of communitising technology based on sustainable university-community collaboration, UMP must become an expert in the existing technologies. “The programmes under the Centres of Excellence UMP apply the high-level technology to provide value creation to the community. “In research, UMP will also increase the research ratio to improve UMP technological capabilities through the Product Development Grant (PDG) Scheme (by department) and Technology Made in UMP (TM@UMP) initiative. “The university will continue to generate advanced technologies for the community through high-impact research that involve patented intellectual property and invention of new first technology in the world. “UMP will also increase the reserve percentage (TDI) and improve reasonable operational efficiency towards financial and best practices sustainability. “With the tagline Communiting Technology, UMP is committed to providing community-driven education, research, and services through social enterprise ecosystem,” he said. Features The trend of 3D printing in higher level TVET skill

By: ASSOCIATE PROFESSOR IR. TS. DR. KUMARAN A/L KADIRGAMA AND ASSOCIATE PROFESSOR IR. DR. WAN SHARUZI WAN HARUN

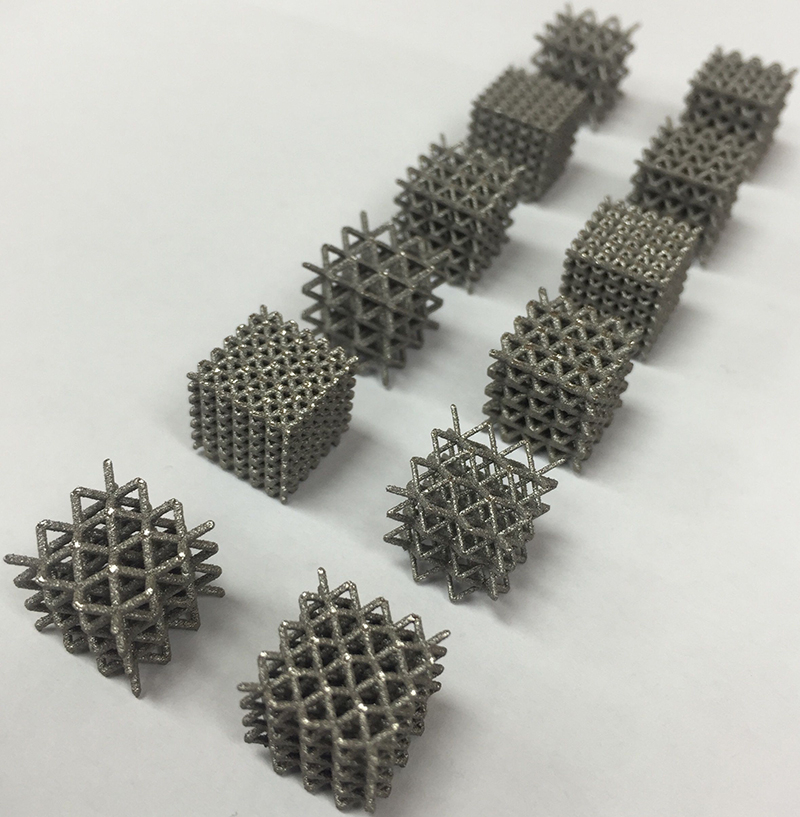

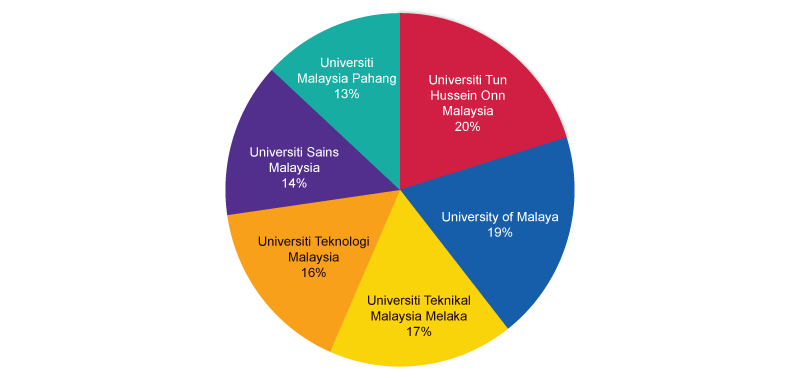

Additive manufacturing is a recent trend in production processes owing to its many benefits around the globe. It can be defined as the process of producing parts through the deposition of material in a layer-by-layer technique. It has been the most searchable research topic since 2000. According to Frost and Sullivan, the value of additive manufacturing is expected to grow at a rate of 15 percent from US$5.31 billion in 2015 to US$21.50 billion in 2025. The industries that are going to contribute 51 percent by 2025 are aerospace, automotive, and medical industries. The 2015 Wohler report stated that a lot of new technology had been evolved in material production for metal printing in the past 10 years compared with plastics. SmarTech Markets Publishing reported that metal printing machines sales grew a significant amount of 89 percent over the past year, as manufacturers turn to three-dimensional (3D) printing. To accommodate the recent trend, UMP collaborates with Qatar University to secure a grant on Qatar National research fund. The total award was RM3.2 million, and UMP obtained RM160,000 from the award. The main objective of the project was to investigate the potential of a more flexible and lightweight titanium alloy femoral stems that can be manufactured using direct metal laser sintering (DMLS) process. A fully porous and functionally graded design was utilised to develop a novel pore cellular structure with compressive properties that are similar to human bone. A 3D finite element model was developed to study and compare the load transfer to the periprosthetic femur when implanted with femoral stems offering different stiffness configurations. Also, fatigue and static tests were done on the fabricated design to study the performance under static and fatigue loadings. Factors affecting the manufacturability and production of the femoral stem through DMLS were also investigated. Total hip arthroplasty (THA) is a common hip replacement procedure. Due to material stiffness mismatch between the bone and implant, loosening the implant is possible, and many patients had to redo the surgery because of the excruciating pains. As such, novel material design for the hip femoral stem is needed to reduce material stiffness mismatch through additive manufacturing. Additive manufacturing will give the surgeon the freedom to customize the hip femoral implant based on the patient’s anatomical data/measurements. This project is essential to produce a printing implant for the patient. The current trend shows an increase in the market for implant products. The project completed successfully, and it is a stepping stone for UMP to involve in additive manufacturing. Figure 1 shows that various IPTA involved in this additive manufacturing field. Figure 2 shows one of the successful printed hip femoral implants by additive manufacturing in Universiti Malaysia Pahang (UMP), in collaboration with Kolej Kemahiran Tinggi MARA (KKTM) Kuantan and Qatar University.

Figure 1. Top higher institutions in Malaysia based on the number of projects related to the 3D printing process between 2000 and 2019.

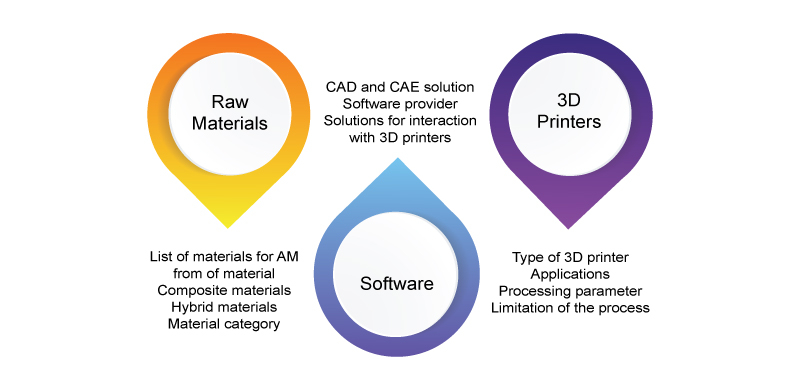

Figure 2: Successful printed hip femoral implant The skill and higher level of learning in additive manufacturing can be included in the TVET national agenda. This skill can meet the country’s demand for highly skilled workers. The 3D printing products can be imported or used in the internal market. Malaysia should focus on this area more critically and impart the skill to the young generation. Three critical subjects can be targeted in the higher level TVET skill for 3D printing process which are (1) types of the 3D printing process, (2) the software used for the interaction with 3D printers, and (2) variety of raw materials (Figure 3).

A highly trained additive manufacturing workforce will need to be skilled in the following multidisciplinary methods: 1. Computer-Aided Design (CAD) Computer-aided design (CAD) is the foundation of additive manufacturing because the result from the 3D is used to make or recreate the geometric structure. That is the reason spatial item configuration is one of the most fundamental skills in additive manufacturing — structuring, adjusting, or improving a current 3D model. 2. Design thinking Additive manufacturing prints from CAD models by including materials layer by layer. This procedure is different from most conventional types of assembling, which expels or subtracts material to frame the ideal shape. Additive manufacturing liberates creators from this large scale manufacturing outlook. The layer-based added substance nature takes into consideration the higher degrees of customization and complex geometries. The most significant part of the plan for additive manufacturing is to recognise and exploit the instruments (generative structure, topology advancement, union, or cross-section structures). 3. Critical thinking and soft skills The focus on hands-on technical skills, the overall level of critical thinking, and problem-solving skills involved in the entire manufacturing process should not be overlooked. Likewise, the value of interpersonal skills such as communication, collaboration, and leadership abilities are equally important for the additive manufacturing workforce. The writers are Senior Lecturers at the Faculty of Mechanical & Automotive Engineering Technology, Universiti Malaysia Pahang. |

- 57 views