The trend of 3D printing in higher level TVET skill

Additive manufacturing is a recent trend in production processes owing to its many benefits around the globe. It can be defined as the process of producing parts through the deposition of material in a layer-by-layer technique. It has been the most searchable research topic since 2000. According to Frost and Sullivan, the value of additive manufacturing is expected to grow at a rate of 15% from US$5.31 billion in 2015 to US$21.50 billion in 2025. The industries that are going to contribute 51% by 2025 are aerospace, automotive, and medical industries.

The 2015 Wohler report stated that a lot of new technology had been evolved in material production for metal printing in the past 10 years compared with plastics. SmarTech Markets Publishing reported that metal printing machines sales grew a significant amount of 89% over the past year, as manufacturers turn to three-dimensional (3D) printing.

To accommodate the recent trend, UMP collaborates with Qatar University to secure a grant on Qatar National research fund. The total award was RM3.2 million, and UMP obtained RM160,000 from the award. The main objective of the project was to investigate the potential of a more flexible and lightweight titanium alloy femoral stems that can be manufactured using direct metal laser sintering (DMLS) process. A fully porous and functionally graded design was utilised to develop a novel pore cellular structure with compressive properties that are similar to human bone.

A 3D finite element model was developed to study and compare the load transfer to the periprosthetic femur when implanted with femoral stems offering different stiffness configurations. Also, fatigue and static tests were done on the fabricated design to study the performance under static and fatigue loadings. Factors affecting the manufacturability and production of the femoral stem through DMLS were also investigated. Total hip arthroplasty (THA) is a common hip replacement procedure. Due to material stiffness mismatch between the bone and implant, loosening the implant is possible, and many patients had to redo the surgery because of the excruciating pains.

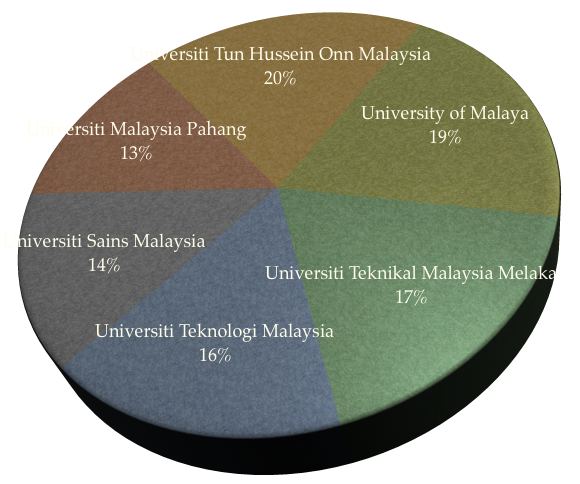

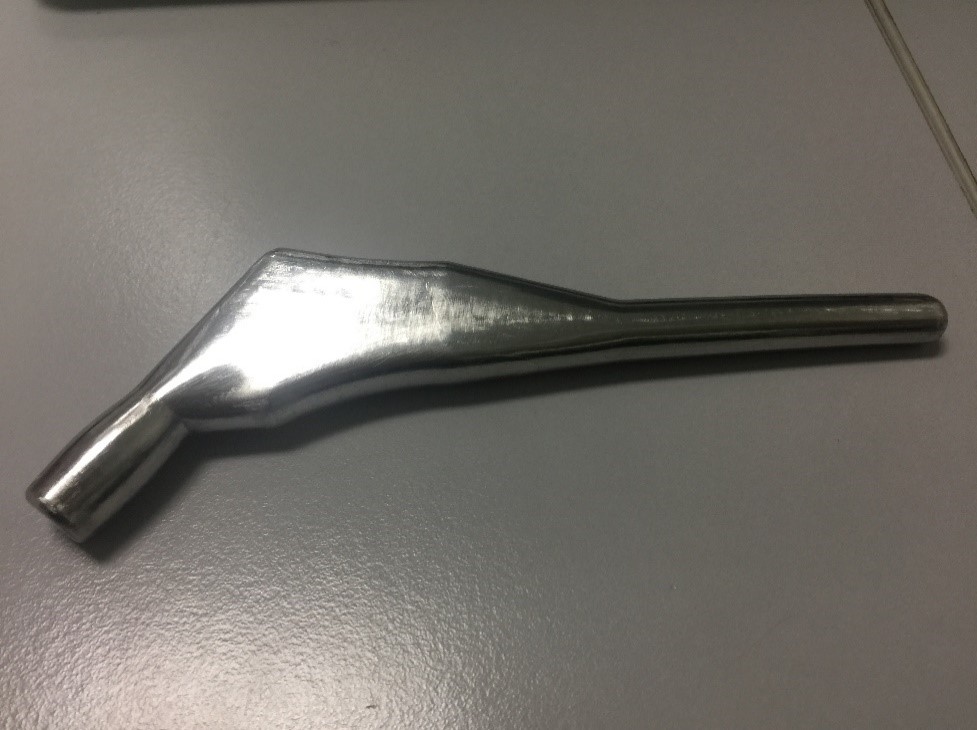

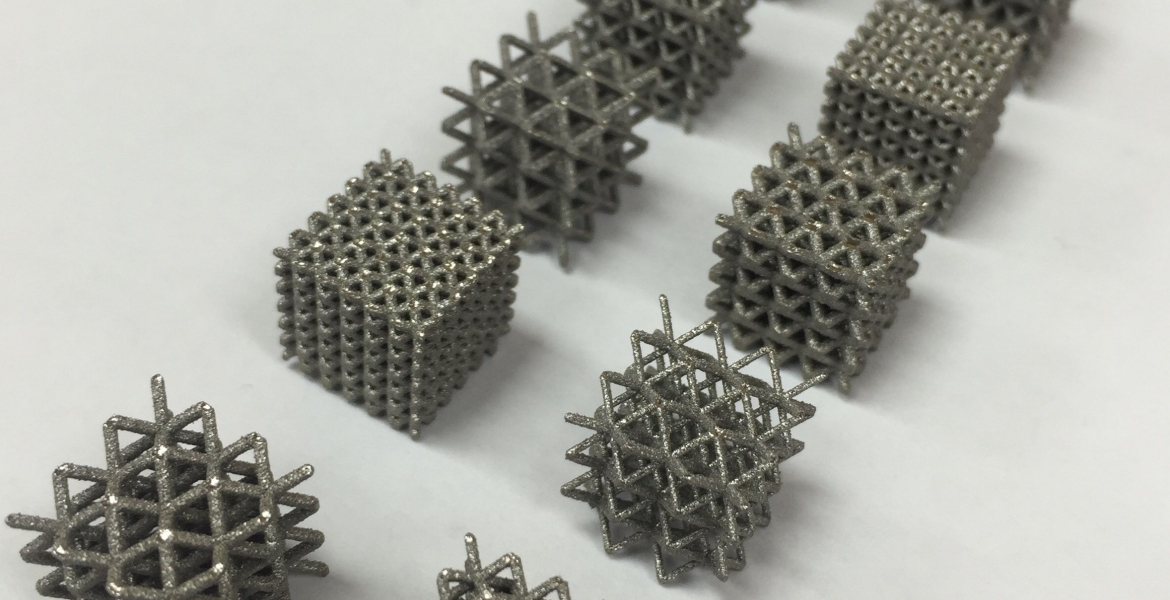

As such, novel material design for the hip femoral stem is needed to reduce material stiffness mismatch through additive manufacturing. Additive manufacturing will give the surgeon the freedom to customize the hip femoral implant based on the patient’s anatomical data/measurements. This project is essential to produce a printing implant for the patient. The current trend shows an increase in the market for implant products. The project completed successfully, and it is a stepping stone for UMP to involve in additive manufacturing. Figure 1 shows that various IPTA involved in this additive manufacturing field. Figure 2 shows one of the successful printed hip femoral implants by additive manufacturing in Universiti Malaysia Pahang (UMP), in collaboration with Kolej Kemahiran Tinggi MARA (KKTM) Kuantan and Qatar University.

Figure 1. Top higher institutions in Malaysia based on the number of projects related to the 3D printing process between 2000 and 2019.

Figure 2: Successful printed hip femoral implant

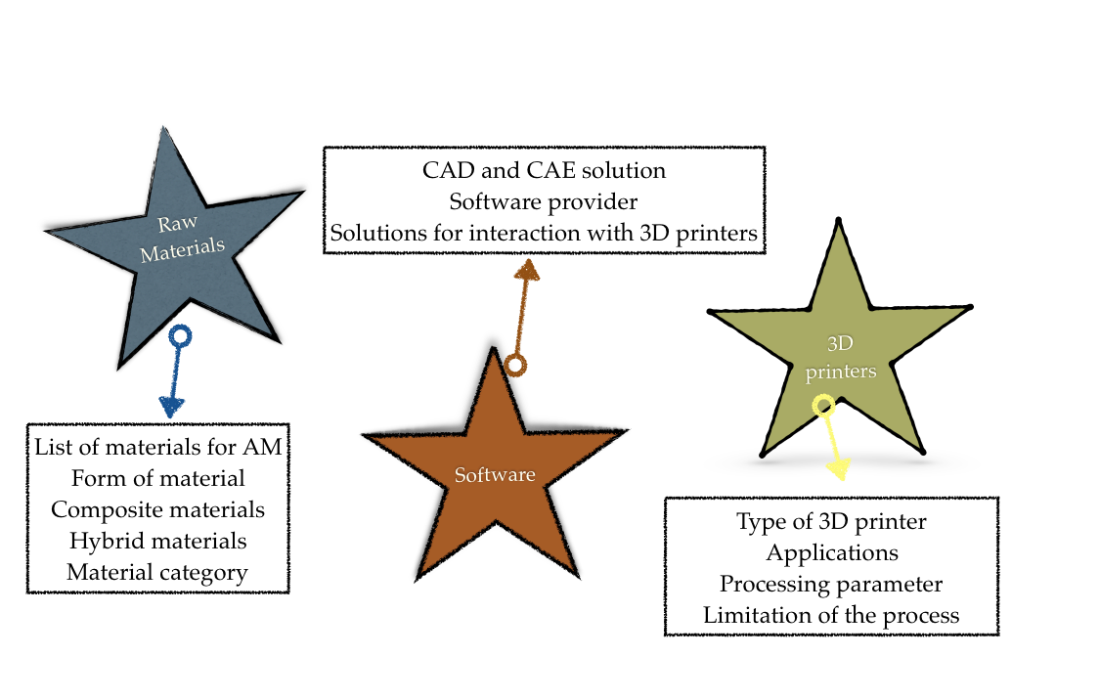

The skill and higher level of learning in additive manufacturing can be included in the TVET national agenda. This skill can meet the country’s demand for highly skilled workers. The 3D printing products can be imported or used in the internal market. Malaysia should focus on this area more critically and impart the skill to the young generation. Three critical subjects can be targeted in the higher level TVET skill for 3D printing process which are (1) types of the 3D printing process, (2) the software used for the interaction with 3D printers, and (2) variety of raw materials (Figure 3).

Figure 3: Potential subjects of 3D printing processes for higher level TVET skill.

A highly trained additive manufacturing workforce will need to be skilled in the following multidisciplinary methods:

1. Computer-Aided Design (CAD)

Computer-aided design (CAD) is the foundation of additive manufacturing because the result from the 3D is used to make or recreate the geometric structure. That is the reason spatial item configuration is one of the most fundamental skills in additive manufacturing — structuring, adjusting, or improving a current 3D model.

2. Design thinking

Additive manufacturing prints from CAD models by including materials layer by layer. This procedure is different from most conventional types of assembling, which expels or subtracts material to frame the ideal shape. Additive manufacturing liberates creators from this large scale manufacturing outlook. The layer-based added substance nature takes into consideration the higher degrees of customization and complex geometries. The most significant part of the plan for additive manufacturing is to recognise and exploit the instruments (generative structure, topology advancement, union, or cross-section structures).

3. Critical thinking and soft skills

The focus on hands-on technical skills, the overall level of critical thinking, and problem-solving skills involved in the entire manufacturing process should not be overlooked. Likewise, the value of interpersonal skills such as communication, collaboration, and leadership abilities are equally important for the additive manufacturing workforce.

The writers are Senior Lecturers at the Faculty of Mechanical & Automotive Engineering Technology, Universiti Malaysia Pahang.

By: Associate Professor Ir. Ts. Dr. Kumaran A/L Kadirgama And Associate Professor Ir. Dr. Wan Sharuzi Wan Harun.

Emai: kumaran@ump.edu.my and sharuzi@ump.edu.my

Edited by: Dr. Rozaimi Abu Samah, Faculty Of Chemical And Process Engineering Technology

- 354 views

Reports by:

Reports by: