Biocomposites: From Waste to Wonder Material

Seriously, have you ever stopped to think that the residue from a palm oil mill or waste from the landfill could literally be the key to saving our planet from plastic?

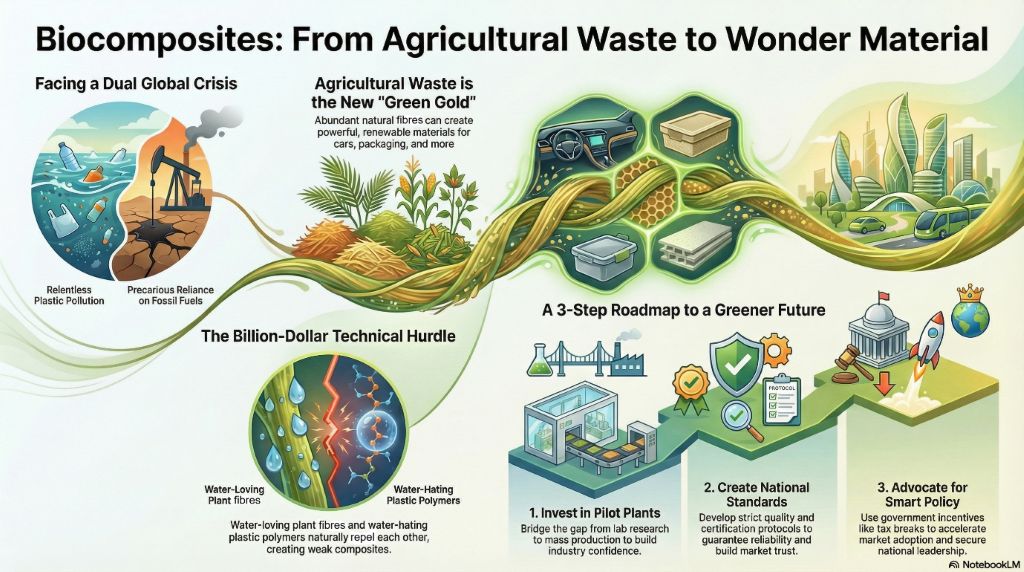

It sounds like science fiction, but it is our imminent reality. We are grappling with two massive global crises: first, the relentless buildup of plastic pollution, and second, the precarious reliance on expensive fossil fuels. For nations blessed with extraordinary agricultural abundance like Malaysia, think of the massive volumes of palm oil fibre, kenaf, and other plant residues generated annually. This crisis actually presents the ultimate strategic opportunity. This is no time for small talk; this is about a massive global pivot. The elegant, strategic solution lies in natural fibre biocomposite technology, which is set to revolutionise manufacturing, drive a circular economy, and define our cleaner future.

Why the World is Obsessed?

Why are top industries suddenly so excited about plant fibres? Because they offer a powerful win-win solution. We are talking about natural, renewable fibres, including jute, hemp, and flax globally, and our very own domestically abundant palm oil empty fruit bunch (EFB), kenaf, and rice husk that can substitute traditional nonrenewable materials. This is because this fibre can be turned into “GOLD”. For instance, in the transport revolution, imagine a lighter car; less weight means less fuel burnt. Top manufacturers are already integrating these materials into vehicle interiors and even semistructural components, dramatically cutting down vehicle mass and shrinking their carbon footprint. The goal is simple: to achieve better fuel economy and lower lifecycle CO2 emissions.

What’s next? Natural fibre can also be fighting the plastic tide. Biocomposites offer a critical lifeline in the fight against pollution. They provide durable materials for packaging and consumer goods that, when engineered correctly, can eventually break down naturally. This will solve the root problem of massive landfill accumulation and ocean pollution without leaving persistent toxic residues.

Bridging the Technical Gap

While the source material is abundant, the application is technically complex. What is the biggest hurdle? The plant fibres we want to use love water (they are hydrophilic), but the plastic polymers we need to bind them with hate water (they are hydrophobic). When you mix them poorly, the resulting material is weak, prone to swelling, degrades quickly, and is useless for high-performance industrial applications.

This fundamental material incompatibility is the billion-dollar technical hurdle that cutting-edge national research must solve. Overcoming it requires precise, high-quality innovation such as sophisticated fibre surface modification techniques and meticulous and advanced material formulation. The results from this innovation will first realise the circular economy. Just imagine we take industrial trash and turn it into certified and high-quality input, stabilising our raw material supply and creating immediate economic value by utilising locally sourced resources. The nations and institutions that develop proprietary techniques to optimise these biocomposites for superior strength, water resistance, and cost-effectiveness will secure a significant competitive advantage in the future of sustainable manufacturing.

Mastering the Science of Sustainability

The critical step in adopting and leading this green technology is localised expertise, focused on resolving the specific technical challenges using indigenous resources. This is where national research bodies and leading technical universities, such as UMPSA, play a crucial role.

Our local focus is on engineering practical solutions that guarantee the quality and performance required by demanding domestic and international industries. By successfully implementing advanced surface modification techniques, our researchers ensure the fibre–matrix adhesion is boosted to a level that provides superior mechanical strength and enhanced durability, even in challenging tropical environments. This means materials engineered here can be trusted for serious applications, moving beyond simple nonstructural uses. This commitment to quality and innovation is how local efforts translate directly into a robust national technological capability, demonstrating that we are a serious source of valuable, high-performance green technology.

The University's Role: A Forward-Looking Plan

Translating scientific success into national economic reality requires a unified, forward-looking plan that effectively bridges the infamous “valley of death” between the lab and the market. To accelerate the transfer of this technology, a resolute, coordinated strategy is paramount, such as first, pilot plant investment. Institutions must prioritise establishing pilot manufacturing facilities to test and refine large-scale processes. This crucial step provides immediate, practical data needed by industry partners for confidence in mass production and commercial investment. Next, we need standardisation and quality assurance partnerships. Active collaboration between national academic bodies and industrial organisations is non-negotiable for co-developing strict standards and certification protocols for locally-made biocomposites. This guarantees long-term reliability and builds trust among all end-users. Finally, we need smart policy advocacy. Policy acts as the necessary accelerator. Research bodies must forcefully advocate for robust government incentives such as tax breaks, preferential procurement, or direct grants for any company committed to utilising verified, domestically sourced biocomposites. This is the surest way to instantly boost market acceptance and solidify the nation’s leadership in the green economy.

Conclusion

The journey from agricultural residue and waste to high-performance industrial material is the defining narrative of sustainability for our era. The strategic research conducted in advanced material science is not merely a regional pursuit; it is a vital contribution to global environmental and economic stability. By intensely focusing on resolving fundamental technical challenges and ensuring the highest quality and innovation in our biocomposite development, our national institutions are actively transforming environmental liabilities into powerful economic assets. Supporting and expanding this area of strategic research is paramount to securing a cleaner, greener, and ultimately more prosperous future for the nation and for the world.

This picture was taken during a BSP4523 Recycling Technology class visit to Gading Senggara Sdn. Bhd., one of the landfills in Jabor, Kuantan. During the visit, students gained first-hand experience of how domestic waste is managed from its arrival by truck to its final disposal at the landfill. They were also introduced to the potential of transforming waste into valuable resources through recycling and waste-to-product conversion. The visit was guided by accompanying lecturers Dr. Nurul Huda Abu Bakar and Dr. Nurjannah Salim from the Faculty of Industrial Sciences and Technology.

By: Ts. Dr. Nurjannah Salim

Email: njannah@umpsa.edu.my

The writer is a Senior Lecturer at the Faculty of Industrial Sciences and Technology, Universiti Malaysia Pahang Al-Sultan Abdullah (UMPSA).

This article represents the author’s personal views and does not reflect the official position of Universiti Malaysia Pahang Al-Sultan Abdullah (UMPSA).

- 65 views

Reports by:

Reports by: