Nanocoolant alternative for cooling elements by UMP researchers

Figure 1: Associate Professor Ts. Ir. Dr. Kumaran Kadirgama and Associate Professor Ts. Dr. Devarajan Ramasamy

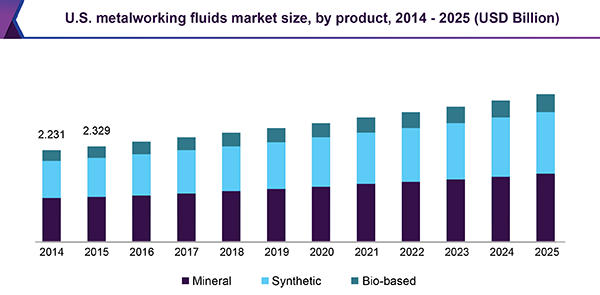

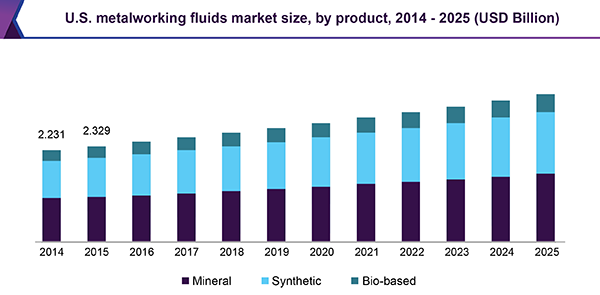

The cooling system is an essential element in our daily life. Even our body needs a cooling system to balance out the temperature among the organs. The automotive and manufacturing industries need a sound cooling system for the equipment and auxiliary devices. With the advancing technology in electric automotive, manufacturing, and high-speed cars, the cooling system has become a more critical element. Metalworking fluid is the standard cutting fluid that has been used widely in many sectors. According to Grand View Research (2018), the global metalworking fluid market in 2017 was valued at USD10.3 billion. Figure 2 shows the annual usage of metalworking fluid. The usage of metalworking fluid has been forecast to increase by 4.4% by the end of 2025. Figure 3 shows the metalworking fluid market size by sector, where machinery sector used about 43% of the total global metalworking fluid annually.

Figure 2: Annual metalworking fluid market size

Source: Grand View Research, June 2018

Figure 3: Metalworking fluid market size by sector

Source: Grand View Research, June 2018

To follow the trend of current technology, the Advanced Nano Lab for Coolant and Lubricant in the Faculty of Mechanical and Automotive Engineering Technology Universiti Malaysia Pahang led by Associate Professor Ts. Ir. Dr. Kumaran Kadirgama and Associate Professor Ts. Dr. Devarajan Ramasamy comes out with nanocellulose-engineered coolant for the cooling system. Nanocellulose is an abundant organic material from plants that reduces the use of harmful coolants in the market. This coolant can be an alternative way to overcome heating problems in manufacturing, automotive, and heating parts in electric vehicles. This coolant can extend a car engine’s life by around 35% and cutting tools by around 25%. In the 2018 and 2018 International Invention, Innovation & Technology Exhibition (ITEX), this product bagged a gold medal. Also, it won platinum and gold medals in the British Invention Show 2018. The work regarding this product has been published in various reputed international journals and conferences.

The product has already been applied for a patent on manufacturing and automotive usage. The research team is currently approached by one of the local industries to help in commercialising the product and for a joint application on the commercialisation grant. The Advanced Nano Lab for Coolant and Lubricant has managed to secure RM 800,000 from national and international agencies. The lab works with the Automotive Excellence Center (AEC) of Universiti Malaysia Pahang to solve the heating problem and expand the engine’s life with a new solution and components machining. Currently, seven students are pursuing their master’s or PhD degrees in this laboratory. This is an excellent opportunity for the students to learn new technology and data using the current technology. This lets them learn in theory and practice, where they need to understand the skills of preparing the liquid and running the experimental test rig. Engine lubrication is another focus of the lab. It can be further enhanced with the new nanomaterials. The current research will focus on the new advancement of nanomaterials to solve the heating problem in manufacturing, solar, and automotive sectors. It shows that Universiti Malaysia Pahang (UMP) can compete with other universities around the world.

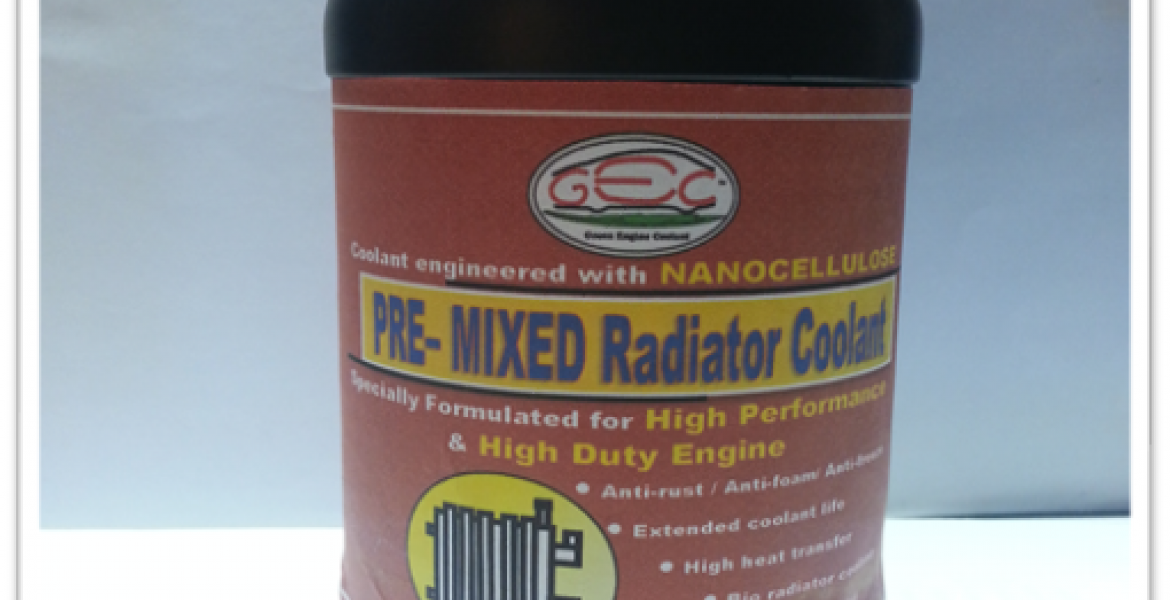

Figure 4: Nanocoolant product made in UMP.

The writers are Senior Lecturers at the Faculty of Mechanical and Automotive Engineering Technology, Universiti Malaysia Pahang (UMP).

By: Associate Professor Ts. Ir. Dr. Kumaran Kadirgama and Associate Professor Ts. Dr. Devarajan Ramasamy

e-mail: kumaran@ump.edu.my and deva@ump.edu.my

- 419 views